Another story of robots during the period of rapid economic growth

In the 1960s, Japan was at a fever pitch with its dramatic economic growth. With the opening of the Tokyo Olympic Games not too far off, inaugurations of things like expressways and the Shinkansen (high-speed bullet train) were happening one after another and people were living increasingly enriched lives. At that time, Astro Boy, the wildly popular robot animation series, had just started its TV broadcast on the airwaves, bringing much excitement into living rooms all across Japan. For most Japanese people, robots were a source of inspiration and represented an image of the future.

But behind the scenes, there was a tale surrounding robots, one not well-known among the public but crucial to industries in Japan. The protagonists in this tale are Joseph Frederick Engelberger, the man recognized as the Father of Robotics, and the employees of Kawasaki.

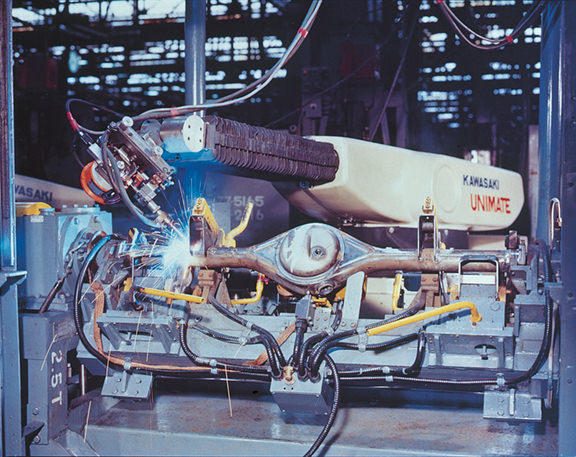

The previous article introduced the “Kawasaki-Unimate”, Japan’s first domestically manufactured industrial robot, its creation, and discussed how its development progressed through working hand-in-hand with the Japanese automobile industry.

The Legacy of Japan’s First Domestically Manufactured Industrial Robot, the “Kawasaki-Unimate”

This article will delve into its prehistory, shining the spotlight on the encounter between Kawasaki and industrial robots.

The world’s first industrial robot venture company established in the United States

The story begins in 1950s United States. American car manufacturers had already set up dedicated machines to speed up factory automation, but, for example in the case of spot welders, the machines could only handle about 70% of the process, leaving the remaining 30% to be finished manually. Further automation was required to improve competitiveness.

In 1956, the then-31-year-old Engelberger, an engineer and entrepreneur, met an engineer at a cocktail party. This man’s name was G.C. Devol, Jr (age 44 at the time), and he was the one responsible for inventing the “Programmed Article Transfer”, a concept which would later be used for modern industrial robots.

Devol explained to Engelberger about his patent-pending concept. His story on robots being able to readily adapt to automation through a method of teaching and playback thrilled Engelberger. The two men instantly clicked and decided to work toward putting robots that would conduct risky operations in place of humans into practical use.

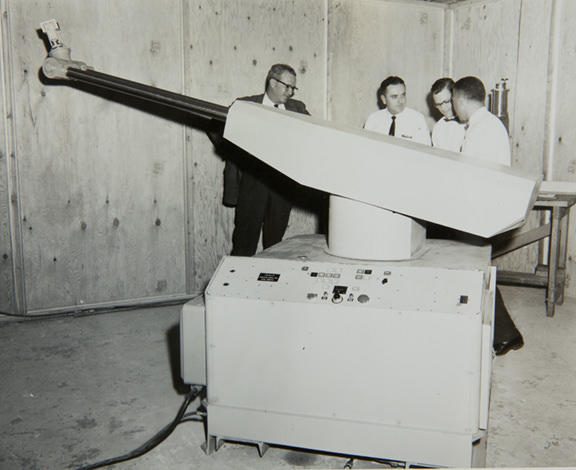

Engelberger actively set out to find business partners in order to achieve their goal. The duo would get funding and complete their first prototype in 1959. Following this achievement, major car manufacturer General Motors (GM) showed an interest and decided to introduce their robots in its factories. And the practical use of industrial robots began from here.

Riding the momentum, Engelberger formed a venture company, Unimation Inc., with Devol in 1961. Without a moment to spare, in the following year, the two successfully completed a working prototype of the Unimate, a robot many would call the world’s first real industrial robot.

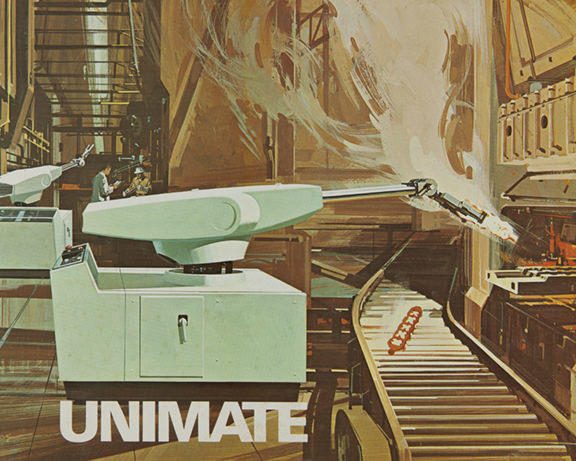

Engelberger foresaw global demand for industrial robots and in preparation for expansion of the business overseas, he laid out a plan that would see local companies being put in charge of production and sales of their robots. For Asian territories, he had his sights set on Japan where industries and technologies were developing at a dizzying pace during the period of rapid economic growth.

Unimation and Kawasaki Aircraft Industries meet

In 1966, Engelberger was invited to Japan where he gave a lecture in Tokyo on industrial robots. During this time, Japan was facing serious labor shortage due to the unexpectedly quick economic growth. Expectations for automation using robots were high and approximately 700 executives attended his lecture. The interaction proved very successful and the question-and-answer session following the lecture lasted two hours.

At the time, Kawasaki Aircraft Industries (who would later merge with Kawasaki Heavy Industries in 1969) took note of the potential of industrial robots. It saw industrial robots becoming its main product line, replacing industrial machines built for a declining fiber industry. In 1967, when word got out that Unimation was looking for a business partner in Japan, the company sent executives to the United States and immediately they started negotiations on a technical partnership.

However, Unimation was initially considering electrical manufacturers for the partnership and Kawasaki Aircraft was not included in its list of seven candidates. Unimation felt electrical manufacturers had the upper hand in terms of machine control.

But Kawasaki Aircraft did not give up; company executives persistently made their way to the United States to continue negotiations. That perseverance paid off as the tide was turning slowly but surely. Eventually, Kawasaki Aircraft won over Unimation and was chosen to become their partner in Japan.

Kawasaki’s technical capabilities were valued in particular. One key component to controlling the Unimate was the hydraulic servo valve. Kawasaki Aircraft had the technology to control machines with micrometer precision, a necessity for the production of fiber spinning pumps. This technology was adaptable to the production of hydraulic servo valves, providing the company with a big advantage. The passion the executives displayed is also said to have been highly admired.

The beginning of the history of the robot industry in Japan

In 1968, Kawasaki Aircraft established the “Office for Promoting Domestic Production of Industrial Robots (IR)”. This led to the development of Japan’s first domestically manufactured industrial robot, the “Kawasaki-Unimate”.

From then on, industrial robots have served a variety of purposes including welding, painting, assembly, handling and palletizing, and Japan, where the implementation of such robotic applications had notably progressed, would become known as a “Robot Kingdom”. Overseas demand for industrial robots is still going strong and according to World Robotics 2017 published by the International Federation of Robotics (IFR), the number of robot units installed is forecasted to grow at an annual pace of more than 15% between now and 2020.

The world still has yet to see the creation of robots like Astro Boy, but with things like the rapid development of artificial intelligence these days, people are putting high expectations on the potential of robots. And robots like Kawasaki’s new humanoid robot that are both powerful and provide support for humans—robots just like Astro Boy—are slowly becoming a reality.

Exploring Robots’ Future with the New Model of Humanoid Robots

To Be the iPhone of the Robot Industry—With 50 Years of Robot Experience, Kawasaki Is on the Move

What do the next 50 years hold in store for robots compared to the past 50? How will humans and robots coexist? The attitude people have towards robots may very well be what sets the compass and dictates the future, so stay tuned as robots become more and more intertwined in the fabric of everyday life.

Photos: The Collections of The Henry Ford