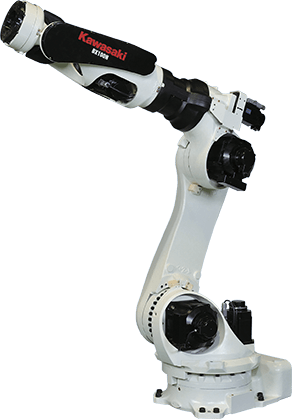

BX100N

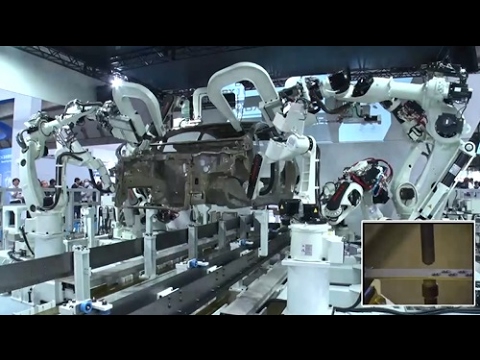

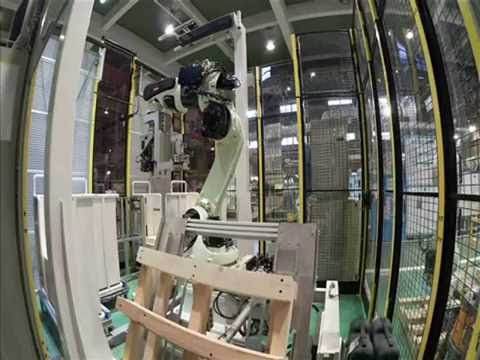

Flexible, Heavy Duty Robot

The BX100N features a hollow wrist for housing cables and hoses. The robust, yet lightweight arm design provides functionality, flexibility and efficiency for maximum spot welding effectiveness and multiple-purpose usage.

※ Before using CAD data, please be sure to read disclaimer here.