With a design backed by decades of robotics industry experience, Kawasaki’s F controllers provide the flexibility users need to take production to the next level. Built for a wide range of application types across the globe, F controllers combine high performance, operability, reliability, and a host of integrated features all in a compact design.

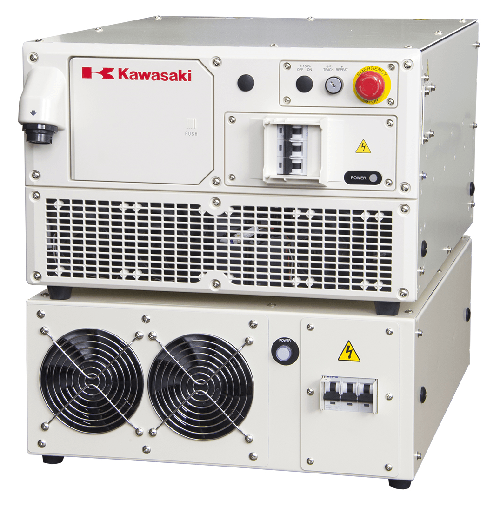

F60

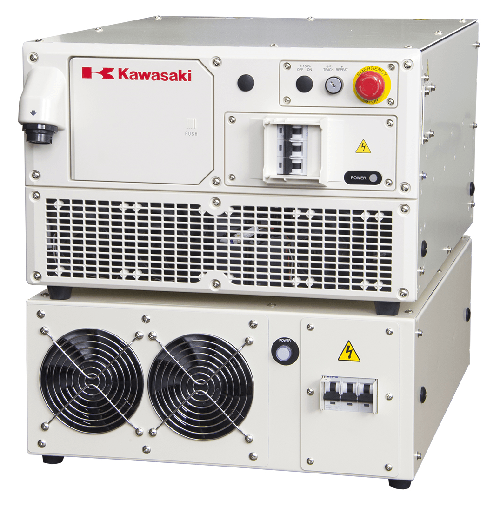

F01

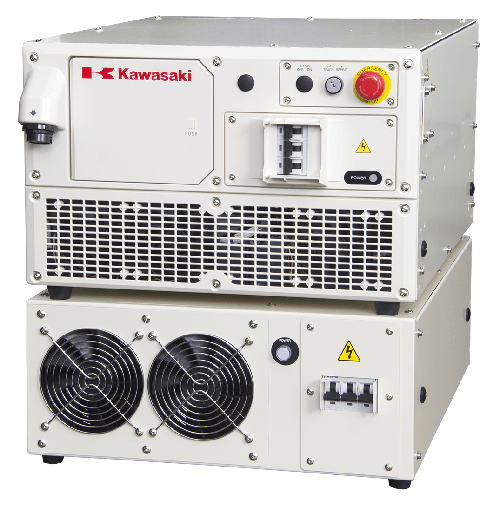

F02

F03