Reducing Costs, Improving Safety

As guardians of a critical resource - the world's food supply – food and beverage operators rely on predictable, easily replicated packaging, handling and transportation solutions to ensure the safety, quality and abundance of their products. In a globalized market for consumables, operators at every step of the supply chain must leverage cutting-edge robotics to remain profitable, competitive and flexible. Kawasaki robots can smooth out dramatic fluctuations in raw material costs and product mix and specifications with cost-effective and flexible in-process handling and end-of-line palletizing automation solutions.

Automation for Modern Food & Beverage Producers

From soda bottling plants to dairy processing facilities, Kawasaki's food and beverage robots meet hygiene requirements and fulfill a wide range of handling processes, including bottle positioning, capping, filling, sterilizing and high-speed picking and sorting as well as repetitive but precise food handling operations like the packaging of irregularly shaped items and variety packs. Elsewhere on the production floor, our reliable robots assist with loading and unloading of packaging and sorting machines as well as palletizing of packaged dairy, meat and beverage products for transfer and shipment. Our cold- and heat-resistant robots can even execute dexterous materials processing and handling operations as well as packing and palletizing processes in adverse working environments in continuous fashion with speed, enhancing productivity and boosting fulfillment while improving worker welfare.

As food and beverage operators demand ever greater precision and safety from their production operations, Kawasaki Robotics continues to develop cutting-edge solutions that reduce waste, boost profit and enhance the safety of the food supply.

Applications

Material Handling

The process of moving materials, parts, and products from one place to another, material handling is performed in almost all industries, not just in the manufacturing industry.

For material handling, industrial robots are most commonly used for various purposes, including high-speed transport of small parts and handling of heavy objects that humans cannot carry.

Palletizing

The process of stacking boxes, bags, bottles, and other products on pallets, palletizing is commonly performed for shipping in the manufacturing industry as well as in the logistics industry. On the other hand, depalletizing is the opposite process, where products are unloaded from pallets in order.

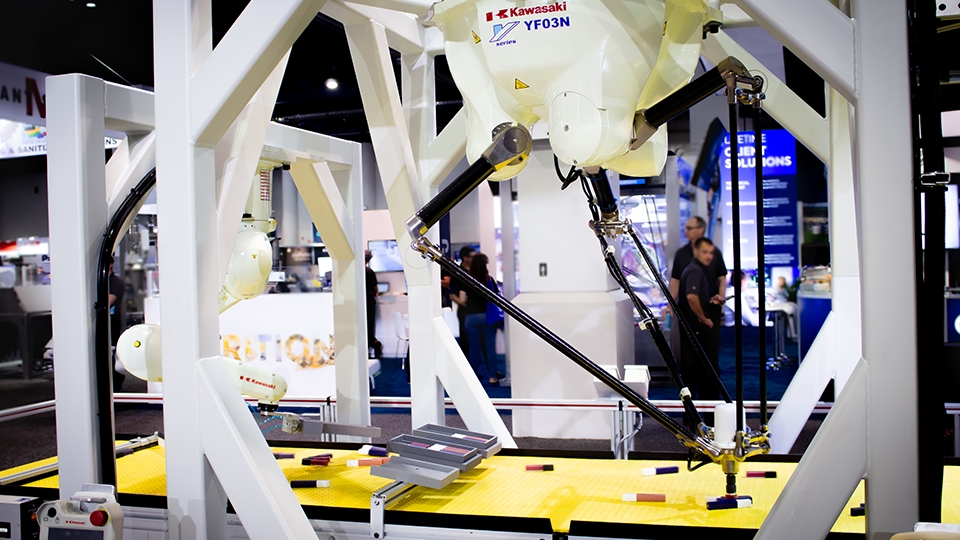

Pick & Place

Picking, also known as “pick and place,” is the process of grabbing workpieces from a conveyor belt and sorting them at high speed.

For this purpose, uniquely shaped robots called the parallel link type (or delta type) are used.