Heavy Duty Robotics Solutions for Hostile Environments

As a persistent economic slump trims global demand, nimble, cost-competitive foundry operators across the developing world have increased competitive pressure for ferrous and non-ferrous metal castings. For manufacturers in the developed world, this supports the business case for the adoption of robust, heat-resistant robots that can withstand the hostile environments and heavy workpieces of modern foundries, provide the flexibility needed to produce quality castings that meet each client’s specifications, and reduce production costs. Kawasaki Robotics’ foundry automation solutions help foundry operators achieve a critical competitive edge while ensuring the safety of their employees.

Cutting Costs, Improving Quality

Our heavy-duty foundry robots can handle payloads of up to 1,500 kg and feature ultra high-torque wrists that effectively, safely manipulate bulky payloads at every step of the manufacturing process. Kawasaki robots use an advanced link design to eliminate the need for an unwieldy counterweight that reduces turning radiuses and shrinks side-to-side clearance. These heat-resistant pieces of equipment can operate in hostile environments while executing delicate handling of molds, casting extraction operations, core assembly and setting, ladling of molten and cooling metal, and additional material removal tasks such as deburring, grinding and polishing. Thanks to flexible positioning capabilities and responsive software programming, these machines can easily be redeployed to handle changing production objectives.

Foundry operators contend with hostile working environments and increasingly competitive global markets, leaving little room for error. Kawasaki Robotics’ foundry automation solutions offer uncompromising performance without sacrificing efficiency, product quality or worker safety.

Applications

Material Handling

The process of moving materials, parts, and products from one place to another, material handling is performed in almost all industries, not just in the manufacturing industry.

For material handling, industrial robots are most commonly used for various purposes, including high-speed transport of small parts and handling of heavy objects that humans cannot carry.

Machine Tending

A critical process in the machinery industry, machine tending involves loading parts into NC machine tools and unloading them after their machining is complete. Loading and unloading processing materials into and out of forging and press machines are also classified as machine tending.

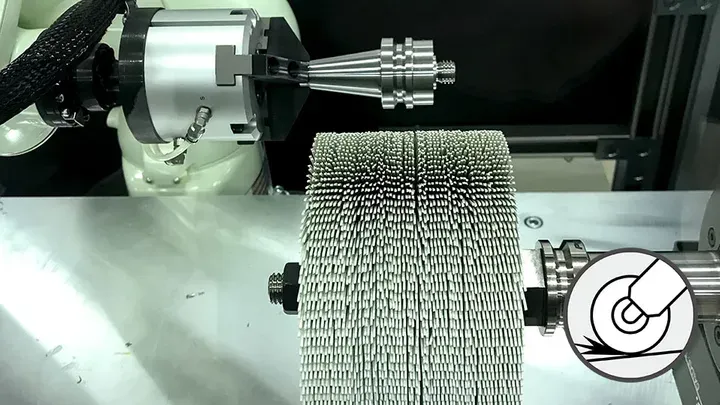

Material Removal

Grinding and deburring is the process of removing protruding burrs from the surfaces of casting and forged products as well as post-welding surfaces.

Involving scrapping off burrs with a grinder, this process can be dirty, dangerous, and demanding where robots can play important roles.