Reduce Machine Overhead Time

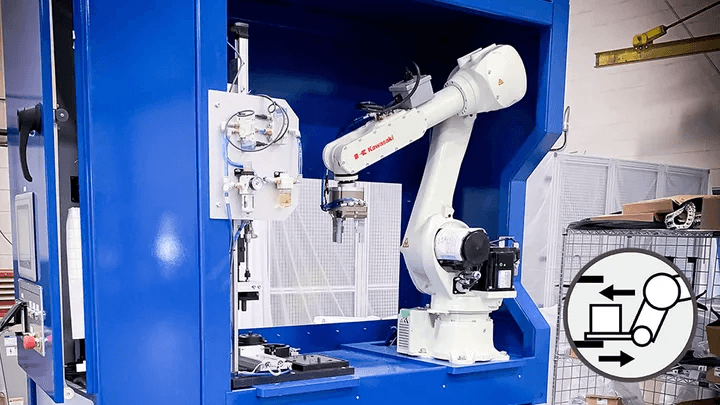

Machine tending can be a simple, automated process of handling product to accommodate a machining process. However, reducing cycle time is crucial because tending a machine is not adding value to the product. Kawasaki is continually developing products to reduce cycle time and offer greater automation flexibility.

Kawasaki offers many products to reduce the time to manipulate product in a machine tending process. The Kawasaki robot software allows for both automatic quick change tooling as well as servo controlled end-of-arm tooling. Many Kawasaki products and services allow for operator interaction with the machine tending process, such as custom Human Machine Interfaces, as well as custom operator safety solutions. Kawasaki robots can either be programmed using the simpler Block Step style programming, or the full Kawasaki AS programming language for the more logic-intensive solutions.

Kawasaki offers standard and custom machine tool automation interfaces, as well as complete machine control and operator safety solutions for your machine tending challenges.

Robots for Machine Tending

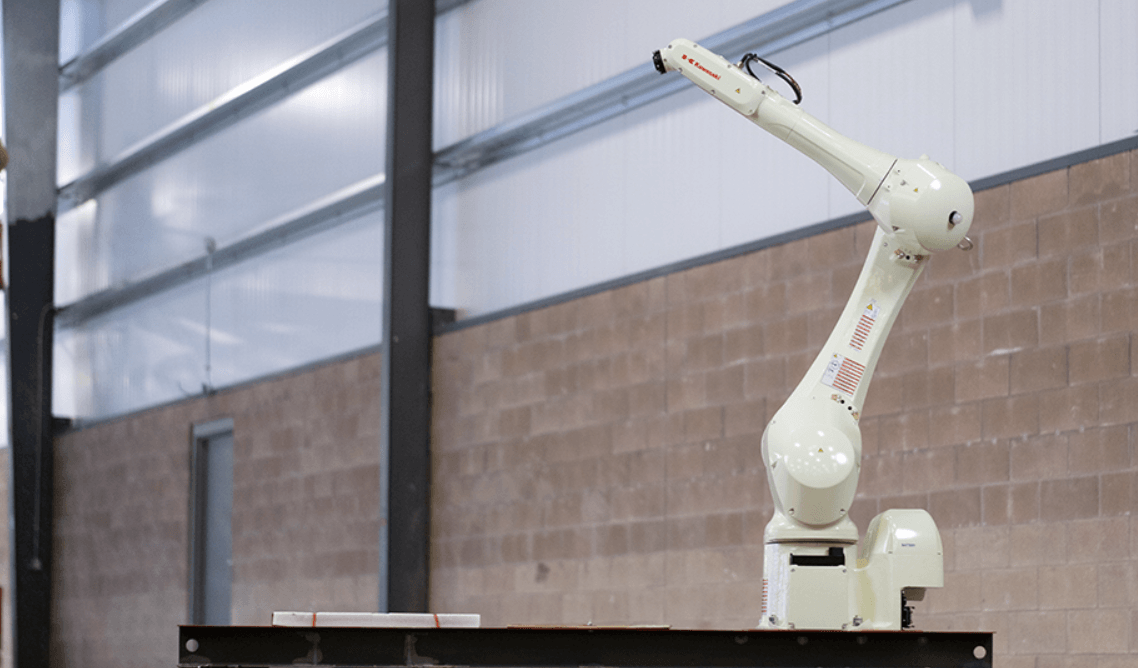

General Purpose Robots (3-80 kg payload)

Our general-purpose R series robots set the benchmark for small-to-medium duty industrial robots.

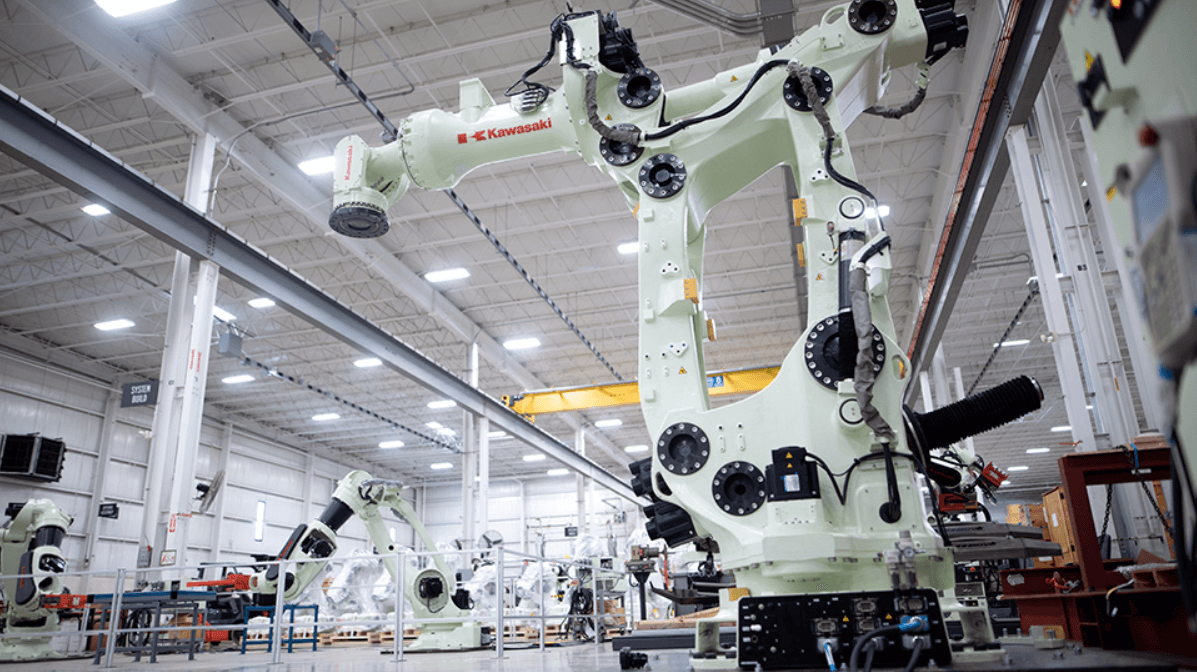

General Purpose Robots (350-1500 kg payload)

Our innovative design gives these models the power to lift heavy loads with ease and accuracy.

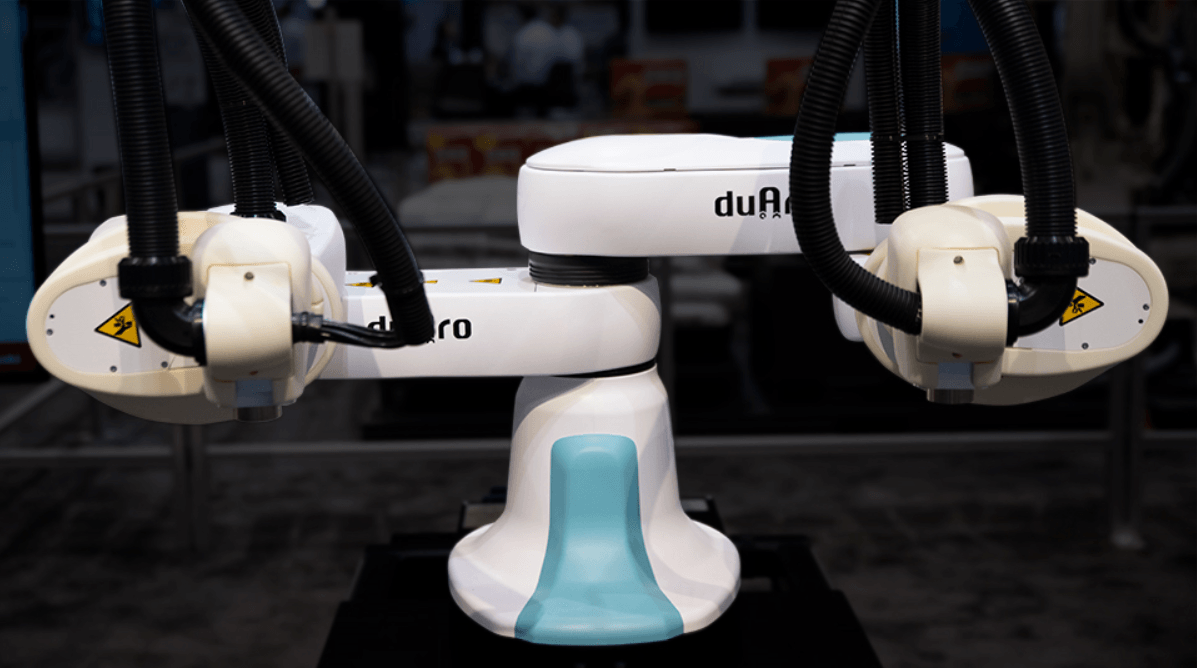

Collaborative Robots

Kawasaki’s unique dual-arm SCARA cobot can collaborate with and work safely alongside humans.