With 50 years of experience in robotics, Kawasaki has accumulated a wide range of application technologies in every field and industry. We support customers‘ needs to automate their production lines and improve productivity. The application examples here only provide a brief look at our vast experience.

Application List

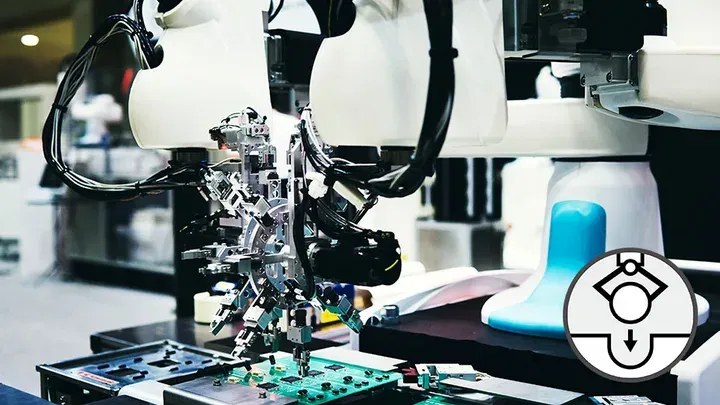

Assembly

The process of combining multiple parts to make components or products, assembly is performed in various manufacturing sectors, including machinery, electronics, and electrical sectors.

Assembly covers various tasks, including assembly of small precision parts and large and heavy workpieces.

Material Handling

The process of moving materials, parts, and products from one place to another, material handling is performed in almost all industries, not just in the manufacturing industry.

For material handling, industrial robots are most commonly used for various purposes, including high-speed transport of small parts and handling of heavy objects that humans cannot carry.

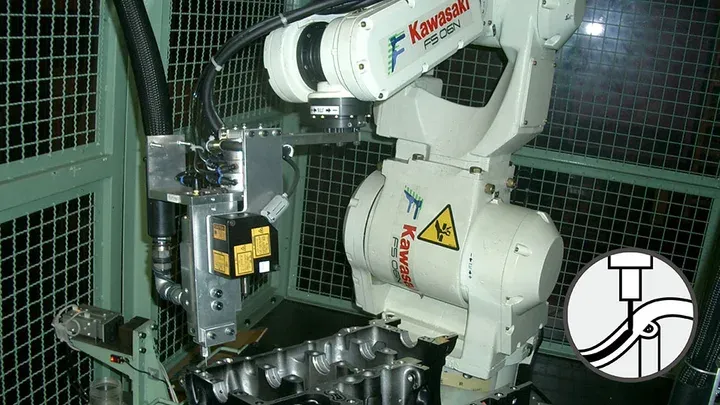

Machine Tending

A critical process in the machinery industry, machine tending involves loading parts into NC machine tools and unloading them after their machining is complete. Loading and unloading processing materials into and out of forging and press machines are also classified as machine tending.

Palletizing

The process of stacking boxes, bags, bottles, and other products on pallets, palletizing is commonly performed for shipping in the manufacturing industry as well as in the logistics industry. On the other hand, depalletizing is the opposite process, where products are unloaded from pallets in order.

Pick & Place

Picking, also known as “pick and place,” is the process of grabbing workpieces from a conveyor belt and sorting them at high speed.

For this purpose, uniquely shaped robots called the parallel link type (or delta type) are used.

Painting

Painting is the process of applying paint on product surfaces, forming a coating film or finish.

Because most paint materials are highly volatile, explosion-proof robots and painting equipment are used for this process.

Sealing / Dispensing

Sealing is the process of applying sealant or adhesive to enhance airtightness and fill the space between materials.

Sealing is performed for many products, such as passenger vehicles and home appliances.

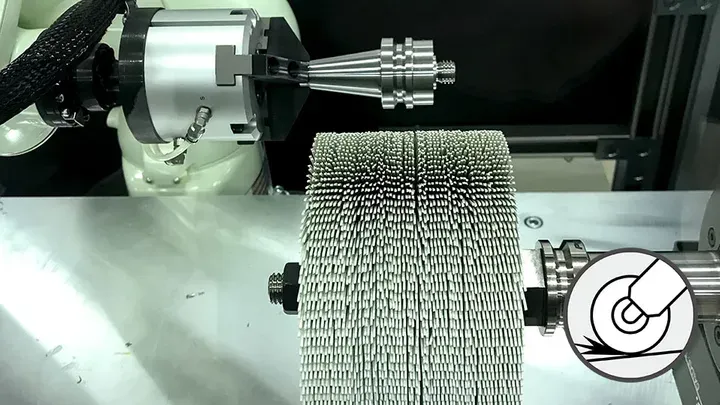

Material Removal

Grinding and deburring is the process of removing protruding burrs from the surfaces of casting and forged products as well as post-welding surfaces.

Involving scrapping off burrs with a grinder, this process can be dirty, dangerous, and demanding where robots can play important roles.

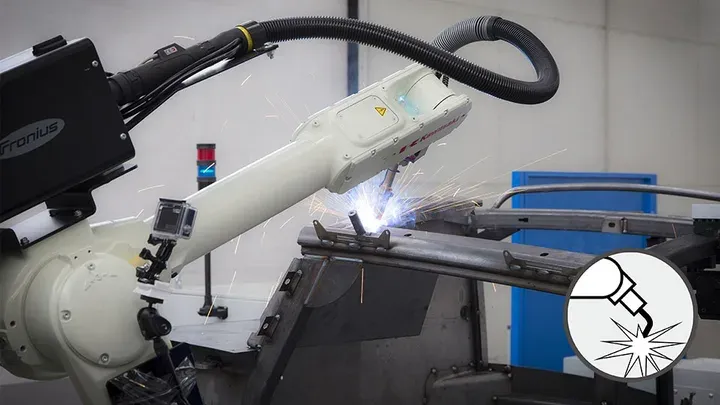

Arc Welding

The welding method that uses arc discharge to join metal materials, arch welding is widely performed in the machinery, metal, and automotive industries. Robots and arc welders are used to join the materials while melting them.

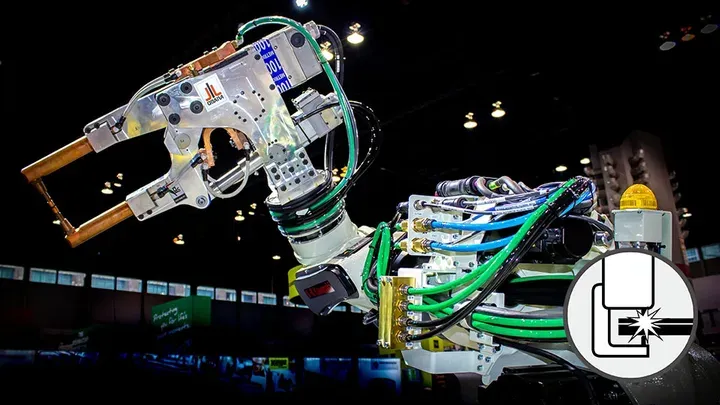

Spot Welding

Spot welding, also known as electric resistance welding, is the process of welding two base materials by applying electric current with an electrode rod and melting them with the resistance heat. Spot welding is so commonly used to weld steel plates of automobile bodies that a large number of robots are used in the automotive industry.

Silicon Wafer Handling

Wafer transfer is the handling of wafers in the front-end process of semiconductor manufacturing equipment.

This process uses clean robots and requires high-precision, high-speed and smooth movement.